YELLOW

BLUE

BLACK

RED

MAJENTHA

- +91 94431 64499, 94425 55880

- Working Hours: Mon - Sat: 9.00 Am to 8.30 pm, Sunday 9.30 Am to 1.30 pm

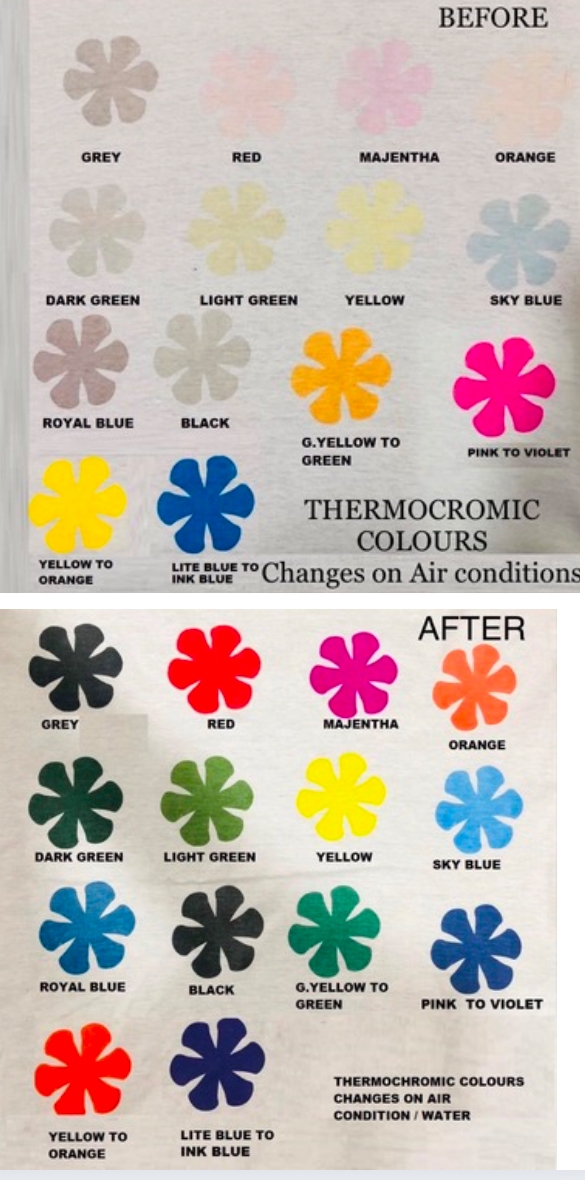

THERMOCHROMIC ( Colour Changes on Temperature )

THERMOCHROMIC ( Colour Changes on Temperature )

Thermochromic is the property of substances to change color due to a change in temperature. It can be Screen Printed on T-shirts and fabrics. It is a very New Product in the market that attracts the buyer easily. Since Thermochromic is waterbased it is possible to adjust the viscosity of this base by dilution with water or reducer to suit the method of application. Our Suppliers by utilizing smart materials to reflect a wide variety of environmental changes, such as a change in mood, change in pressure, change in temperature, change in smell. with the core technology of micro-capsulization, they not manufacture a variety of functional colour changing products, but also actively engages in the application.

-

COLOURS

-

APPLICATION PROCESSA) DIrect Mixing of basic colors By the three primary colors ( Blue, Red, Yellow), you can create new colors as your expectation. For Example. Thermochromic Yellow mixture with Thermochromic Blue gives Thermochromic green. when exposed in sunlight it looks colorless. when the temperature of the print fabric is kept below 18 C degree the Green color appears. B) Coating Layer The color can be changed from one to another by applying a combination of Thermochromic inks with regular pigments in multiple-layer coatings for Example Print base coat with regular color like Blue ink and over that print Thermochromic Yellow which gives Green color when the temperature of the printed fabric is kept below 18 C degree and remains blue color when exposed sunlight.

-

MESH49~52S(120-130) mono-multi filament for under base Clear and colours

-

SQUEEGEES55/65 sore hardness: For excellent opacity on printing under base clear, are recommended. 65 sore hardness : For wet on wet for multi color printing.

-

CURINGFor maximum fastness, prints are to be cure at 150ºC/302°F. Airflow recommended is 1500 cfm/ 46cmm for 2 minutes.